When Pulverizing Coal What Is A Mining Mill Used For

Coal Pulverization System: Explosion Prevention and

Raw coal is conveyed from the storehouse by a belt conveyer. Then it is lifted to the entrance level of a vertical cylindrical mill by a bucket elevator, and an electromagnet is

get price

进一步探索

Pulverizer Fire and ExplosionsFire Protection Guidelines for Handling and Storing PRB 根据热度为您推荐•反馈

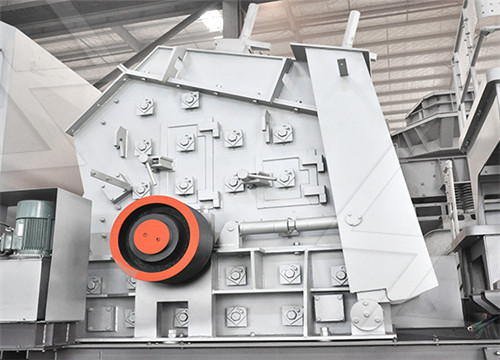

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such

get price

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. The hot gases used should have a low oxygen content,

get price

Pulverizer Machines RuggedReliable Williams Patent

Pulverizers are commonly used in the coal industry but can be suited for a variety of applications. The main purpose of these machines is to process materials and act as size reduction equipment. Pulverizing mills and

get price

Industrial Crushing EquipmentPulverizing Mill Manufacturer

Industrial Pulverizing Equipment. One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to

get price

Mining Industry: What is a coal mill? Quora

We know that, only processed by milling machine, coal can be used as fuel. This is to increase the combustion rate of coal, and avoid the waste of resources. Raymond Mill is

get price

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification.

get price

Coal mill pulverizer in thermal power plants SlideShare

2012年11月17日15. 10.Bowl Mill Bowl mills are employed to pulverize the pre-crushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The mill output can be easily varied,

get price

Coal Pulverizers an overview ScienceDirect Topics

The pulverized coal boiler can also be modernized to burn various forms of biomass. In existing power units, the limitation for adding a biomass boiler operating on a common

get price

Coal Pulverizer Power Plant Pall Corporation

Further pulverization of coal is achieved as the smaller coal particles are ground through attrition against each other and the grinding face. Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling

get price

Pulverizer Machines RuggedReliable Williams

The main purpose of these machines is to process materials and act as size reduction equipment. A pulverizer reduces materials like Limestone and gypsum at high speeds resulting in smaller particle sizes. Centrifugal

get price

Vertical Grinding Mill (Coal Pulverizer) Explained

Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. The hot gases used should have a low oxygen content,

get price

Coal Crushers Coal PulverizersMills Williams

William’s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite

get price

Mining Industry: What is a coal mill? Quora

Answer (1 of 3): To grind coal to fine powder for further firing at the huge huge burners fitted in the water walls of boilers in the coal fired thermal power plants mainly to heat water and convert to high pressure, high temperature steam, steam to be fed in turbines connected to electric genera...

get price

Coal mill pulverizer in thermal power plants

2012年11月17日15. 10.Bowl Mill Bowl mills are employed to pulverize the pre-crushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The mill output can be easily varied,

get price

Coal Pulverizers an overview ScienceDirect Topics

The pulverized coal boiler can also be modernized to burn various forms of biomass. In existing power units, the limitation for adding a biomass boiler operating on a common turbine is its capacity. However, in systems where combined boilers can supply various turbines, the addition of a biomass boiler is not a problem. View chapter Purchase book

get price

Industrial Coal Pulverizes Used Pulverizing Mills Wabash Power

Industrial PulverizersMills. Wabash maintains the largest inventory of usedreconditioned Raymond mills in the United States. The Raymond brand is considered the gold standard for pulverizing coal and minerals. Wabash has been an industry leader for over 40 years supplying refurbished mills and components for a variety of industries

get price

Why Pulverized Coal is Used in a Power Plant

2010年1月29日Burning the coal in the combustion process to release the energy in the fuel. Why Pulverizing ? The basic requirement of coal combustion is that all the carbon particles in coal should get sufficient air to burn and release the heat. Coal normally is available to power plants in large lumps ranging from 2 mm to 50 mm size.

get price

What Is The Working Principle Of High-pressure Vertical Mill?

High-pressure vertical grinding mill is a common large-scale pulverizing equipment. Its pulverizing process is advanced and intelligent, and it can grind many materials. but also extends to the grinding of pulverized coal, non-metallic minerals such as limestone, calcite, and metal minerals such as manganese and lithium.

get price

Fire and Explosion Hazards in Cement

1) Coal Pulverizing Coal is often the main fuel source used to heat the cement kiln. Coal pulverizers are required to grind the coal from the bulk storage size to a smaller particle diameter to use in the kiln. Coal

get price

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification. Failure to understand all four and their inter-relationship is most often the

get price

Industrial Crushing EquipmentPulverizing Mill Manufacturer

Industrial Pulverizing Equipment. One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to crush coal. Stedman crushers, mills, and grinders are used in nearly every mineral and mining industry. Whether you are processing coal, rock, salt, iron ore,

get price

Pulverizer Manufacturers Suppliers IQS Directory

High Speed Coal Pulverizers Attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling media. Crushers Designed to reduce the size of large, dense materials such as

get price

Pulverizer Machines RuggedReliable Williams

The main purpose of these machines is to process materials and act as size reduction equipment. A pulverizer reduces materials like Limestone and gypsum at high speeds resulting in smaller particle sizes. Centrifugal

get price

Vertical Grinding Mill (Coal Pulverizer) Explained

Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. The hot gases used should have a low oxygen content,

get price

Coal Crushers Coal PulverizersMills Williams

William’s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite

get price

Mining Industry: What is a coal mill? Quora

We know that, only processed by milling machine, coal can be used as fuel. This is to increase the combustion rate of coal, and avoid the waste of resources. Raymond Mill is a common equipment to produce coal powder. Its output size is 80-325mesh.

get price

Coal Pulverizers an overview ScienceDirect Topics

The pulverized coal boiler can also be modernized to burn various forms of biomass. In existing power units, the limitation for adding a biomass boiler operating on a common turbine is its capacity. However, in systems where combined boilers can supply various turbines, the addition of a biomass boiler is not a problem. View chapter Purchase book

get price

Coal mill pulverizer in thermal power plants

2012年11月17日15. 10.Bowl Mill Bowl mills are employed to pulverize the pre-crushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The mill output can be easily varied,

get price

Industrial Coal Pulverizes Used Pulverizing Mills Wabash Power

Industrial PulverizersMills. Wabash maintains the largest inventory of usedreconditioned Raymond mills in the United States. The Raymond brand is considered the gold standard for pulverizing coal and minerals. Wabash has been an industry leader for over 40 years supplying refurbished mills and components for a variety of industries

get price

Why Pulverized Coal is Used in a Power Plant

2010年1月29日Burning the coal in the combustion process to release the energy in the fuel. Why Pulverizing ? The basic requirement of coal combustion is that all the carbon particles in coal should get sufficient air to burn and release the heat. Coal normally is available to power plants in large lumps ranging from 2 mm to 50 mm size.

get price

Identifying a Pin Mill for Optimal Performance and

2018年3月21日A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. and

get price

What Is The Working Principle Of High-pressure Vertical Mill?

High-pressure vertical grinding mill is a common large-scale pulverizing equipment. Its pulverizing process is advanced and intelligent, and it can grind many materials. but also extends to the grinding of pulverized coal, non-metallic minerals such as limestone, calcite, and metal minerals such as manganese and lithium.

get price

Coal mining and transportation U.S. Energy Information Administration

Mining coal. Coal miners use large machines to remove coal from the earth. Many U.S. coal deposits, called coal beds or seams, are near the earth's surface, but others are deep underground.Modern mining methods allow U.S. coal miners to easily reach most of the nation's coal reserves and to produce about three times more coal in one hour than in

get price

What Is Pulverizing Plant Crusher Mills, Cone Crusher, Jaw

Coalcoke pulverizing plant,small scale coke plant,rod mill The liming Mining Machine is custom designed to reduce your operating costs and increase your mine production by getting your mining, haulage and conveying systems to be Duck-bill dinosaurs had plant-pulverizing teeth more advanced

get price

Set-point optimization and control of coal-pulverizing systems

2009年5月25日Stable control of a coal-pulverizing system with ball-tube mill usually cannot be hold due to some disturbances, such as coal hardness and steel ball wearing, etc. A hierarchical structure with a direct control layer and a set-point optimization layer is applied to this typical system. Based on steady-state gain models of different operating

get price

Radioactive Waste From Uranium Mining and Milling

2022年7月29日Radiation Facts. Regardless of how uranium is removed from rock, the extraction process creates radioactive wastes. If not managed properly, mining waste and mill tailings can contaminate the

get price