Mining Mill Section For Cement

Cement Plant an overview ScienceDirect Topics

96 行The cement production cost significantly increases when CO 2 capture is applied

get price

6 Points in the Production Process to Optimize Cement

作者: Ankush Koul

Simulation study of cement plug micro-annulus in milling section

Generally, several cement plugs with certain lengths must be placed in the wellbore for P&A. Plug position requires a combination of geological factors, wellbore structure, and integrity (Kuip et al., 2011; Achang et al., 2020).As shown in Fig. 1 a, a cement plug can be placed directly in the casing to cover the wellbore cross-section when the cement

get price

New section milling technology designed for restricted

2017年7月3日A section mill is used primarily for milling sections in the casing. Milling can usually be done as fast as cuttings can be circulated

get price

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise ensures delivery of your Premier™ mill or Select™ mill based on your operational needs. When choosing your equipment we not only keep in mind mill performance, but

get price

Mining Activities, Cement Production Process and Quality

2022年7月4日There are two open pit mines, namely Livwezi and Chikoa, at Shayona Cement factory in Kasungu. They conduct all mining activities including drilling, blasting and hauling. All three brands of...

get price

Start Englisch CEMTEC

TECHNOLGIES FOR THE CEMENT AND MINING INDUSTRY OUR PORTFOLIO INDIVIDUAL PRODUCTION THAT MEETS THE HIGHEST QUALITY STANDARDS OUR PRODUCTS CARRER WITH CEMTEC BECOME A PART OF OUR TEAM CURRENT JOB OFFERINGS TECHNOLGIES FOR THE CEMENT AND MINING INDUSTRY OUR

get price

Products for cement and mining I

When you choose products for cement plants and mining plants, you’ll get high-quality and durable equipment that delivers the best value long-term. has more than 140 years of experience

get price

Cement Plant an overview ScienceDirect Topics

The cement production cost significantly increases when CO 2 capture is applied (95% for gas-liquid absorption and 63% for calcium looping) as well as CO 2 avoided cost. However, calcium looping method shows far better values than gas-liquid absorption. View chapter Purchase book Energy Management Amine Allouhi,

get price

6 Points in the Production Process to Optimize

2019年7月30日The first step in the cement process is the recovery of the limestone and sometimes the extraction of clay. Online elemental analyzers can monitor material chemistry in real time, allowing for adjustments that

get price

Mining Activities, Cement Production Process and Quality Control

2022年7月4日There are two open pit mines, namely Livwezi and Chikoa, at Shayona Cement factory in Kasungu. They conduct all mining activities including drilling, blasting and hauling. All three brands of...

get price

SAP for Mills and Mining SAP Community

SAP for Mill Products and Mining. SAP is the leading provider of software solutions for the Mill Products and Mining industries. We offer a broad innovative solution portfolio for the sectors mining, metals, building materials, and products, cement and concrete products, pulp, stone and packaging, plastic manufacturing, and textiles.

get price

Cement Manufacturing Process Phases Flow Chart

2012年8月30日Rotating ball mill Cement Manufacturing Process Phase VI: Packing and Shipping Transportation of cement from silos Material is directly conveyed to the silos (silos are the large storage tanks of

get price

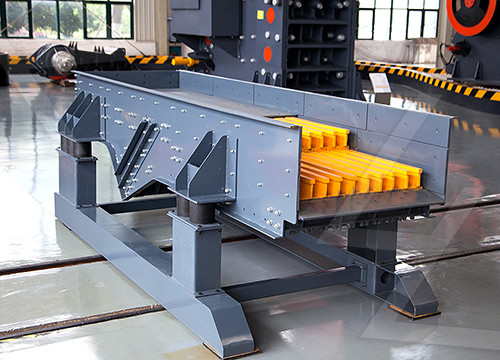

Ball Mill for Sale Mining and Cement Milling

We provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple

get price

Modeling of the Thermal Efficiency of a Whole Cement Clinker

Cement clinker manufacturing is an energy-intensive process, often involving fuel (pulverized coal, oil and gas) combustion/firing. Fuel firing (mainly pulverized coal in China) is required to achieve and maintain thermal conditions for carbonate decomposition and clinker calcination; it is also a process with significant CO 2 emissions [1,2].Global

get price

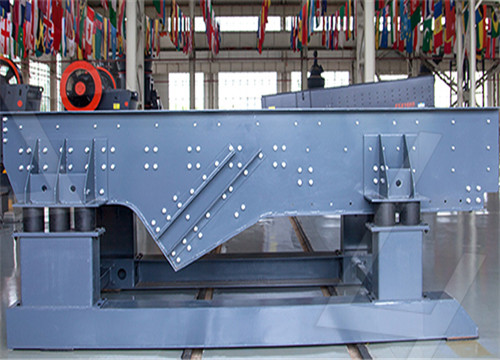

cement mill foundation cross section MiningQuarry Plant

Below is some information about the products equipment, cement ball mill cross section Allegany County Division of Permits and Land Development cement, surface bonding mortar or other per IRC 406 Vapor barrier required for sub-

get price

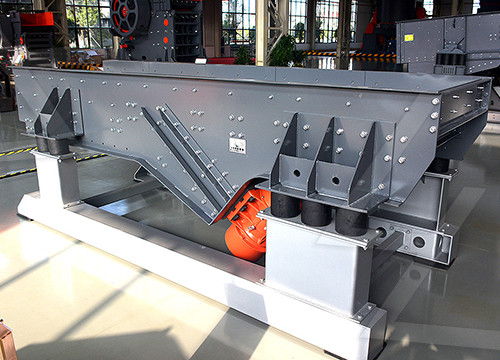

Cement Mill Machinery/Cement Mill For Sale of New product

Our Cement Ball mill is widely used in many industries, such as black metal, nonferrous metal mining section, nonmetal mines, construction, electricity, coal, traffic, light industry and so on. The energy saving ball mill produced by our company adopts rolling bearing support. Comparing with other supports, the rolling bearing can save 10-20%

get price

Process control technology for optimum performance

Optimise your operations with ’s process control technologies. We offer a wide range of technologies designed to optimise the performance of your cement plant or mineral processing operations. Whether you are looking to cut energy and maintenance costs, lift your productivity or automate your machinery, we can help.

get price

Grinding Mining industry Siemens Global

2023年3月2日Mining 13 days to revamp four ore mills The customer could rely on timely delivery despite a very tight project schedule all components including FLENDER couplings, twelve synchronous motors (4,000/4,850 kW), and SINAMICS SL150 cycloconverters were transported via express airfreight delivery.

get price

PGNAA Improves Process and Quality Control in Cement Production

2014年6月17日PGNAA improves stockpile and raw mix control. Cement producers who must meet increasingly stringent customer and regulatory requirements are turning to PGNAA cross belt analyzers for elemental composition data to improve quality control, process efficiency, energy savings and waste reduction. Cement raw materials must be

get price

drawing layout detail section stone crusher MiningQuarry Plant

2013年3月16日drawing for coal equipment in cement plant Gold Ore Crusher Mining Equipment,Stone Crushing Machine,Concrete Batching In Cement Plant we have worked on the detailing of Coal Mill Section Pulverizer Machine Drawing Details Crusher Mills, Cone stone crusher machine 2d drawing plan. (Fuzhou) Co.,

get price

Products for cement and mining I

When you choose products for cement plants and mining plants, you’ll get high-quality and durable equipment that delivers the best value long-term. has more than 140 years of experience

get price

Cement Plant an overview ScienceDirect Topics

The cement production cost significantly increases when CO 2 capture is applied (95% for gas-liquid absorption and 63% for calcium looping) as well as CO 2 avoided cost. However, calcium looping method shows far better values than gas-liquid absorption. View chapter Purchase book Energy Management Amine Allouhi,

get price

Grinding mills for mining and minerals processing Metso Outotec

Mill liners Metallic, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types. Grinding mill upgrades Whether old or new, we can help bring your grinding mill to the next level with a wide variety of upgrades available. Grinding mill inspections Avoid undetected grinding mill issues.

get price

Grinding Mining industry Siemens Global

2023年3月2日Mining 13 days to revamp four ore mills The customer could rely on timely delivery despite a very tight project schedule all components including FLENDER couplings, twelve synchronous motors

get price

SAP for Mills and Mining SAP Community

SAP is the leading provider of software solutions for the Mill Products and Mining industries. We offer a broad innovative solution portfolio for the sectors mining, metals, building materials, and products, cement and concrete products, pulp, stone and packaging, plastic manufacturing, and textiles. On-Demand Now International SAP

get price

PGNAA Improves Process and Quality Control in

2014年6月17日PGNAA improves stockpile and raw mix control. Cement producers who must meet increasingly stringent customer and regulatory requirements are turning to PGNAA cross belt analyzers for elemental

get price

Ball Mill for Sale Mining and Cement Milling

We provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple

get price

Modeling of the Thermal Efficiency of a Whole Cement Clinker

Cement clinker manufacturing is an energy-intensive process, often involving fuel (pulverized coal, oil and gas) combustion/firing. Fuel firing (mainly pulverized coal in China) is required to achieve and maintain thermal conditions for carbonate decomposition and clinker calcination; it is also a process with significant CO 2 emissions [1,2].Global

get price

cement mill foundation cross section MiningQuarry Plant

Below is some information about the products equipment, cement ball mill cross section Allegany County Division of Permits and Land Development cement, surface bonding mortar or other per IRC 406 Vapor barrier required for sub-

get price

Cement Mill Machinery/Cement Mill For Sale of New product

Our Cement Ball mill is widely used in many industries, such as black metal, nonferrous metal mining section, nonmetal mines, construction, electricity, coal, traffic, light industry and so on. The energy saving ball mill produced by our company adopts rolling bearing support. Comparing with other supports, the rolling bearing can save 10-20%

get price

Process control technology for optimum performance

Optimise your operations with ’s process control technologies. We offer a wide range of technologies designed to optimise the performance of your cement plant or mineral processing operations. Whether you are looking to cut energy and maintenance costs, lift your productivity or automate your machinery, we can help.

get price

Cement Plant Energy Optimisation PDF Mill (Grinding)

The thermal energy contributes nearly half of the energy cost in a cement plant. The. major consumption is the fuel used in the kiln. The other thermal energy consumers. are. 1. Coal furnace Used for drying of coal in some plants. 2. Raw mill furnace Used for drying of raw meal during starting of the plant.

get price

latest technology for grinding in cement and mining

For the new VRM cement grinding system, Related Mining Plant: new grinding cement plants open in wani area Go to Product Center. latest recruitment in cement industry of mining foreman, Mining Engineer : Saurashtra Gujarat, Cement industry Sr. Engineer / Asst. Manager Mines Cement industry

get price