Limestone Composition Suitable For Fgd

Flue-Gas Desulphurization an overview ScienceDirect

Most FGD technologies use an alkali sorbent, such as limestone (calcium carbonate), quicklime (calcium oxide), hydrated lime (calcium hydroxide), or sometimes sodium and magnesium carbonate and ammonia, to capture the acidic sulfur compounds from the

get price

Power Flue Gas Desulfurization (FGD) Plants

Wet Limestone-Gypsum FGD Process This process is suitable for large-scale flue gas treatment, and can uses a low cost absorbent (limestone), and produces stable and valuable by-products (gypsum). Typical system

get price

Flue-gas desulfurization Wikipedia

OverviewHistoryMethodsSulfuric acid mist formationFGD chemistryFacts and statisticsAlternative methods of reducing sulfur dioxide emissionsSee also

Methods of removing sulfur dioxide from boiler and furnace exhaust gases have been studied for over 150 years. Early ideas for flue gas desulfurization were established in England around 1850. With the construction of large-scale power plants in England in the 1920s, the problems associated with large volumes of SO2 from a single site began to concern the public. The SO 2 emissions problem did not receive much attention until 1929, when the House of Lords upheld th

get price

Chemistry of FGD Blowdown US EPA

FGD BLOWDOWN The characteristics of FGD blowdown will vary depending on the chloride concentration that drives the number of times the water can be concentrated. The

get price

Flue Gas Desulfurization (FGD) for ELG Compliance Evoqua

The purge stream contains contaminants from coal, limestone, and make-up water. It is acidic and supersaturated with gypsum, with high concentrations of total dissolved solids

get price

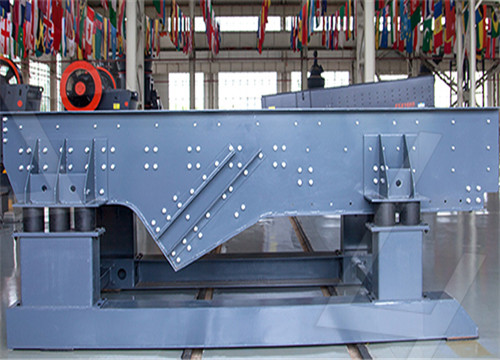

Suitable FGD limestone mill, low investment in power plants

2023年2月15日The limestone powder for FGD is a minimum of 90% passing 325 mesh. Transportation: deliver the limestone to the power plant in a closed tank car, sent into the limestone powder bin by a hydraulic

get price

INVENTORY OF ILLINOIS LIMESTONE RESOURCES

High-calcium limestone, which has proven to be one of the best scrubber stones in FGD systems, is found only in some layers within the Mississippian Burlington Limestone.

get price

REVIEW OF HANDLING AND USE OF FGD MATERIAL

2012年1月10日Like wet FGD materials, the chemical composition of spray dryer material residues depends on the sorbent used for desulfuriz ation and the proportion of fly ash

get price

TSPL TECHNICAL SPECIFICATION FOR WET LIMESTONE FGD

TECHNICAL SPECIFICATION FOR WET LIMESTONE FGD SYSTEM AND AUXILIARIES CONTENTS SHEET 1 OF 1 TSPL VOLUME I CONTENTS Section Specification No.

get price

Limestone FGD Scrubbers: User's Handbook : Project

The complete report, entitled "Limestone FGD Scrubbers: User's Handbook." (Order No. PB 82-106 212; Cost: $37.50, subject to change) will be available only from: National

get price

Flue Gas Desulfurization Wastewater Treatment

2009年3月1日Many plants are required to remove SO x emissions from the flue gas using flue gas desulfurization (FGD) systems. The three leading FGD technologies used in the U.S. are wet scrubbing (85% of the

get price

Status of Flue Gas Desulphurisation (FGD) systems from coal

2015年3月15日The abatement capacity of major, minor, and trace elements and the fate of trace pollutants during wet limestone FGD, as well as the features of wet limestone FGD by-products are discussed. It can be stated that wet limestone FGD system is the FGD process most widely used because of its high desulphurisation performance and low

get price

Air Pollution Control Technology Fact Sheet US EPA

Typical sorbent material is limestone, or lime. Li mestone is very inexpensive but control efficiencies for limestone systems are limited to appr oximately 90%. Lime is easier to manage on-site and has control efficiencies up to 95% but is significantly more cost ly (Cooper 2002). Proprietary sorbents with reactivity-

get price

Wet Flue Gas Desulfurization with Lime/Limestone

The limestone slurry containing calcium sulphite is collected in the absorber sump. The limestone used for cleaning the flue gases is continuously added to the absorber sump to ensure that the cleaning capacity of the

get price

Experienced materials in wet limestone-gypsum FGD system

1998年12月31日@article{osti_350049, title = {Experienced materials in wet limestone-gypsum FGD system}, author = {Hasegawa, S and Iwashita, K and Ochi, E and Higuchi, T}, abstractNote = {This study was made on the corrosion resistivity evaluation method used for material selection in the Wet Limestone-Gypsum FGD system with examples of

get price

Experienced Materials in Wet Limestone-Gypsum FGD System

1998年3月22日The wet limestone-gypsum process FGD plant is broadly divided into two types-ash-separated (dual- loop) process, and ash-mixed (single-loop) process-depending on whether the flue gas is separated from ash before being led into the absorber or led as it is into the absorber mixed with ash.

get price

INVENTORY OF ILLINOIS LIMESTONE RESOURCES FOR FGD

High-calcium limestone, which has proven to be one of the best scrubber stones in FGD systems, is found only in some layers within the Mississippian Burlington Limestone. Pennsylvanian limestones are variable in purity but may contain up to 90 percent CaCO3.

get price

TSPL TECHNICAL SPECIFICATION FOR WET LIMESTONE

TECHNICAL SPECIFICATION FOR WET LIMESTONE FGD SYSTEM AND AUXILIARIES CONTENTS SHEET 1 OF 1 TSPL VOLUME I CONTENTS Section Specification No. Rev No. Title No. Of Sheets A1 TCE.10461B-H-6006-01 P0 Introduction and Scope of Enquiry 4 A2 TCE.10461B -H-6006-01 P0 Instruction to Bidder 25 FILE NAME:

get price

Limestone FGD Scrubbers: User's Handbook EPA

EPA-600/8-81-017 August 1981 LIMESTONE FGD SCRUBBERS: USER'S HANDBOOK by D. S. Henzel and 6. A. Laseke PEDCo Environmental, Inc. Cincinnati, Ohio 45246 x and E. 0. Steam Generator Design The scope of this handbook does not include guidelines for selection of the most suitable steam generator for a powerplant. Limestone

get price

METHOD AND SYSTEM FOR PERFORMANCE OPTIMIZATION OF

State of the art techniques used for Flue Gas Desulpharization (FGD) process monitoring fail to comprehend the relationship between various process parameters, which is crucial in determining the performance of a FGD process being monitored. The disclosure herein generally relates to industrial process monitoring, and, more particularly, to a method and

get price

FGD (Limestone / Seawater)

The wet limestone gypsum process uses limestone as an absorbent for the desulphurization of flue gases and produces gypsum that is suitable for industrial use as an end product. The flue gases coming from boiler are directed into the absorber where the pollutants SO 2,HCl, HF are removed before flue gas is released into the atmosphere

get price

Catalysts Free Full-Text Synthesis of a SiO2/Co(OH)2

Sulfur and nitrogen oxides (SOX/NOX) are the primary air toxic gas pollutants emitted during fuel combustion, causing health and environmental concerns. Therefore, their emission in flue gases is strictly regulated. The existing technologies used to decrease SOX/NOX content are flue gas desulfurization, which necessitates high capital and operating costs,

get price

Scrubbing: Optimizing Flue Gas Desulfurization Technologies Is Essential

2006年9月1日It is the acid generated by absorption of the SO 2 into the liquid that drives the limestone dissolution process. Equation 2: CaCO 3 + 2H + Ca+2 + H 2 O + CO 2 ↑. Equations 1 and 2, when

get price

Flue Gas Desulfurization Wastewater Treatment

2009年3月1日The limestone contributes iron and aluminum (from clay minerals) to the FGD wastewater. Limestone is typically pulverized in a wet ball mill, and the erosion and corrosion of the balls...

get price

Status of Flue Gas Desulphurisation (FGD) systems from coal

2015年3月15日The abatement capacity of major, minor, and trace elements and the fate of trace pollutants during wet limestone FGD, as well as the features of wet limestone FGD by-products are discussed. It can be stated that wet limestone FGD system is the FGD process most widely used because of its high desulphurisation performance and low

get price

Experienced Materials in Wet Limestone-Gypsum FGD System

1998年3月22日The wet limestone-gypsum process FGD plant is broadly divided into two types-ash-separated (dual- loop) process, and ash-mixed (single-loop) process-depending on whether the flue gas is separated from ash before being led into the absorber or led as it is into the absorber mixed with ash.

get price

Scrubbing: Optimizing Flue Gas Desulfurization

2006年9月1日It is the acid generated by absorption of the SO 2 into the liquid that drives the limestone dissolution process. Equation 2: CaCO 3 + 2H + Ca+2 + H 2 O + CO 2 ↑. Equations 1 and 2, when

get price

Use of Limestone for SO2 Removal from Flue Gas in the Semi-Dry FGD

2000年10月1日As limestone desulfurization can release CO2, when limestone desulfurization was replaced with steel slag of equal desulfurization ratio, CO2 emissions could be reduced by 279.6 kg and limestone

get price

TSPL TECHNICAL SPECIFICATION FOR WET LIMESTONE

TECHNICAL SPECIFICATION FOR WET LIMESTONE FGD SYSTEM AND AUXILIARIES CONTENTS SHEET 1 OF 1 TSPL VOLUME I CONTENTS Section Specification No. Rev No. Title No. Of Sheets A1 TCE.10461B-H-6006-01 P0 Introduction and Scope of Enquiry 4 A2 TCE.10461B -H-6006-01 P0 Instruction to Bidder 25 FILE NAME:

get price

Limestone FGD Scrubbers: User's Handbook EPA

EPA-600/8-81-017 August 1981 LIMESTONE FGD SCRUBBERS: USER'S HANDBOOK by D. S. Henzel and 6. A. Laseke PEDCo Environmental, Inc. Cincinnati, Ohio 45246 x and E. 0. Steam Generator Design The scope of this handbook does not include guidelines for selection of the most suitable steam generator for a powerplant. Limestone

get price

FGD (Limestone / Seawater)

The wet limestone gypsum process uses limestone as an absorbent for the desulphurization of flue gases and produces gypsum that is suitable for industrial use as an end product. The flue gases coming from boiler are directed into the absorber where the pollutants SO 2,HCl, HF are removed before flue gas is released into the atmosphere

get price

Catalysts Free Full-Text Synthesis of a SiO2/Co(OH)2

Sulfur and nitrogen oxides (SOX/NOX) are the primary air toxic gas pollutants emitted during fuel combustion, causing health and environmental concerns. Therefore, their emission in flue gases is strictly regulated. The existing technologies used to decrease SOX/NOX content are flue gas desulfurization, which necessitates high capital and operating costs,

get price

METHOD AND SYSTEM FOR PERFORMANCE OPTIMIZATION OF

State of the art techniques used for Flue Gas Desulpharization (FGD) process monitoring fail to comprehend the relationship between various process parameters, which is crucial in determining the performance of a FGD process being monitored. The disclosure herein generally relates to industrial process monitoring, and, more particularly, to a method and

get price

Dynamic optimization oriented modeling and nonlinear

2020年3月1日At first, a mathematical model of the FGD process is deduced which is suitable for NMPC structure. To equipoise the model's accuracy and conciseness, the wet limestone FGD system is separated into several modules. Based on the conservation laws, a model with reasonable simplification is developed to describe dynamics of different

get price

NORMS FOR INSTALLATION OF FGD for NEW

WET LIMESTONE BASED FGD Page 3 of 4 TECHNOLOGY SELECTION The So 2 reduction technology shall be done considering following factors: 1: Sulphur Content in Coal. Power plants are advised to minimize this interconnection time by taking suitable measure so that the “Opportunity cost“ associated with plant shutdown may have least

get price

Power plant units with wet limestone FGD (under construction)

Download Table Power plant units with wet limestone FGD (under construction) from publication: Źródła sorbentów wapiennych do odsiarczania spalin w Polsce w kontekście potrzeb krajowej

get price

Environmental Impact of Calcium Sulfoaluminate Cement

13 小时之Ordinary portland cement (OPC) manufacturing contributes to about 5–8% of the CO2 emissions globally and its consumption is expected to increase. Finding alternative to OPC is a global issue in the recent times. Calcium sulfoaluminate (CSA)-based binder is...

get price